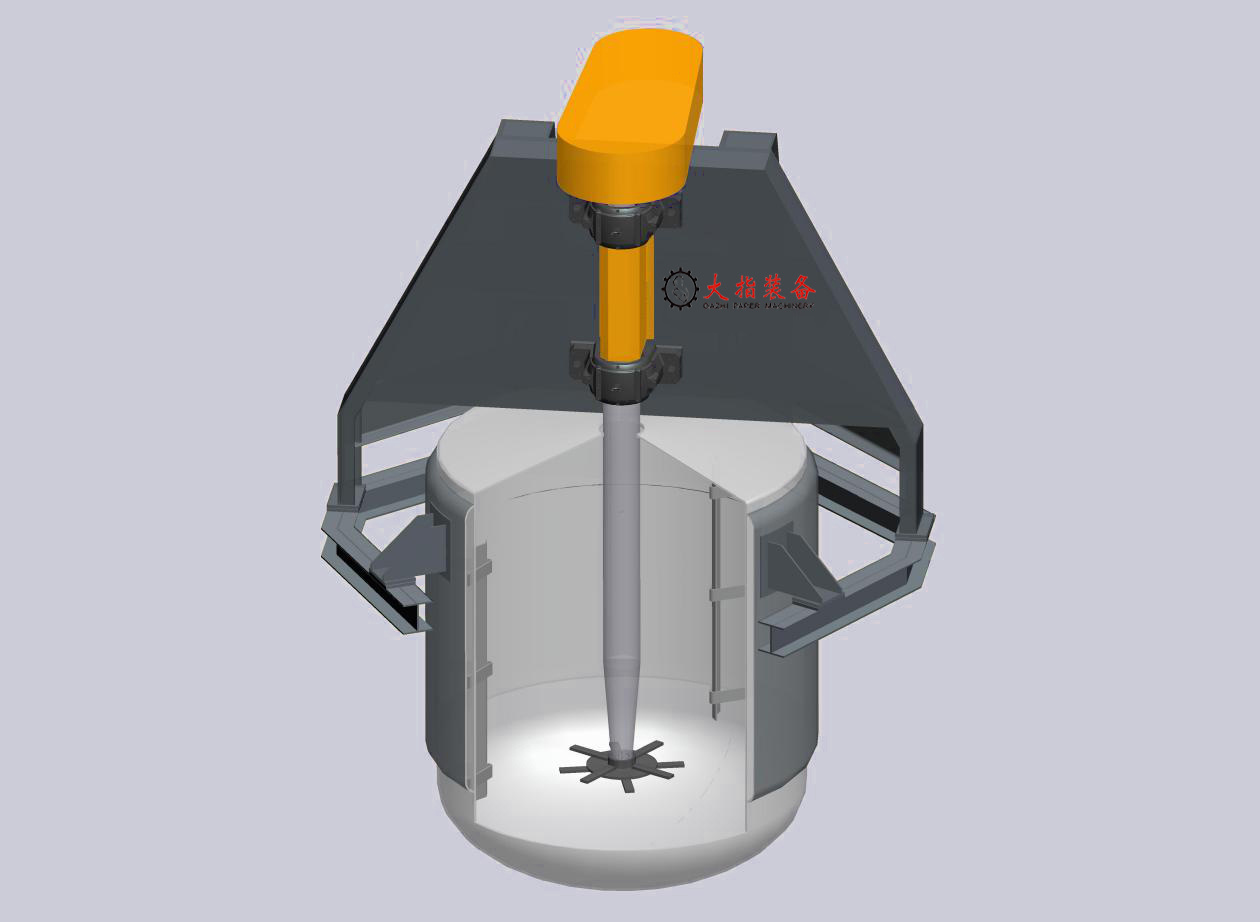

Integra® Mixer

Brief introduction The mixer is made as per common use and modular standard design, which could be easily used to cope with mixing of coating material, pigment, filler, etc. in the papermaking process, for example, to be applied together with intelligent ingredient management system for continious and highly efficient process of Solid-liquid dispersion with high solid content.

Key words

Category:

Product Description

Brief introduction

The mixer is made as per common use and modular standard design, which could be easily used to cope with mixing of coating material, pigment, filler, etc. in the papermaking process, for example, to be applied together with intelligent ingredient management system for continious and highly efficient process of Solid-liquid dispersion with high solid content.

|

Advantage |

Application |

|

Maximum preparation of solid content |

Porcelain mixing |

| All-purpose recipe operation |

CaCO3 mixing |

| Simple maintenance requirement | Filler mixing |

|

No michnical sealing |

Coating preparation |

| Equipped with weighing module to precisly measure the fed material | High viscosity material |

|

Mixer D type,C type and F type;(D)dispersion,(C) coating material,(F)filler |

||||

|

Mixer dimension |

5400 |

4000 |

2800 |

1500 |

|

Dia. |

1900mm |

1750mm |

1600mm |

1250mm |

|

Tank height |

2000mm |

1750mm |

1500mm |

1250mm |

|

Working volume |

5.4m³ |

4.0m³ |

2.8m³ |

1.5m³ |

|

Output RPM |

300-1450rpm |

|||

|

Total height (Reference) |

4000mm |

4300mm |

3900mm |

3300mm |

|

Weight sensor |

3×10t |

3×10t |

3×5t |

3×3t |

|

Net weight(Reference)) |

5000kg |

3800kg |

3500kg |

2500kg |

|

D type power |

160kW |

132kW |

110kW |

75kW |

|

C type power |

132kW |

110kW |

90kW |

55kW |

|

F type power |

110kW |

90kW |

75kW |

55kW |

Pageup:

Related Products

Request a Quote