Integra® High Speed Curved Roll

The main structure of curved roll, a set of rotary sleeves mounted on a fixed curved shaft, is mainly used in processing equipments such as paper, film, textiles and similar products. The material such as the web or film is stretched by the rotation of the roller to eliminate the wrinkle.

Key words:

Integra® High Speed Curved Roll

Category:

Product Description

The main structure of curved roll, a set of rotary sleeves mounted on a fixed curved shaft, is mainly used in processing equipments such as paper, film, textiles and similar products. The material such as the web or film is stretched by the rotation of the roller to eliminate the wrinkle.

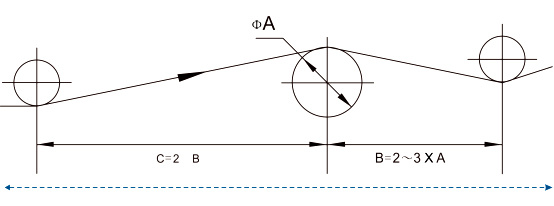

Working principle is shown as below:

Wrap angle is from 10 to 100 degree basedon web material.

The right installation method is to make the curved roll vertical against the material run direction. The distance B betweencurved roll and rear guide roll is twice to three times the diameter A of curved roll and the distance Cbetween curved roll and the guide roll before it is twice B for good spreader result.

A paper machine is a collective term for a complete set of equipment that forms a paper web for pulp, including a main unit such as a pulp box, a mesh unit, a pressing unit, a drying unit, a calendering machine, a paper rolling machine, and a transmission unit, as well as auxiliary systems such as steam, water, vacuum, lubrication, and heat recovery.

A machine that produces paper by dewatering the pulp water suspension that meets the requirements of papermaking through a filter, mechanical extrusion dewatering, and drying processes. The paper machine consists of three main parts: forming, pressing, and drying, which complete the above process. It is equipped with necessary finishing, coiling, and transmission devices, as well as auxiliary systems such as pulp supply, pulp and white water circulation, vacuum, ventilation and exhaust, paper loss treatment and lubrication, and self-control.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Related Products

Integra®-Platform Special Paper Machine

Integra®- Platform Culture Paper Machine

Request a Quote

Domestic Business Department

Contact person: jiguang.liu

Mobile: +8613243038828

Tel: +86-0391-7268787

Fax: +86-0391-7268787

Email: jiguang.liu@dazhipaper.com

Overseas Business Department

Contact person: Mike. Li

Mobile: +86 15538973150

Tel: +86-0391-7230928

Email: marketing@dazhipaper.com

Copyright © Henan Dazhi Papermaking Equipment and Engineering CO., LTD.